Dry Filtration Baghouses

Amerair manufactures a complete line of standard and custom baghouses for general ventilation and hot gas process operations. All of our designed units incorporate heavy duty welded construction, ease of access and maintenance, state of the art instrumentation and controls, efficient and conservative cleaning systems and superior bag installation and replacement features.

Pulse-Jet baghouses feature both 5″ and 6″ diameter bag designs. Depending on the size of the installation requirements, high pressure standard bag technology or medium pressure long bag technology can be selected to create the best solution both technically and financially in initial and long term operating cost. With a multitude of different design options and configurations, Amerair offers the custom baghouse solution to satisfy any requirement.

Reverse-Air baghouses are provided in both structural and welded plate construction for all of the various available bag diameter and lengths. The 12″ diameter design is general applicable when the gas volume to be cleaned is in excess of 300,000 ACFM. The reverse-air baghouse has proven throughout the years to be the best choice on many large metallurgical applications where total annualized capital and operating cost are thoroughly evaluated.

Mechanical shaker baghouse designs are predominately used on difficult metallurgical applications where no other method of bag cleaning is sufficient for the service. Amerair’s shaker baghouses are supplied in all welded factory constructed modules reducing the cost of field installation.

Both low pressure reverse pulse as well as pulse-jet cartridge collectors are available for a broad range of specialty applications across a number of different industries.

Negative pressure penthouse roof enclosed Pulse Jet Baghouse designed to filter 406,000 ACFM of ash laden flue gases from a 105 egawatt cogenerating facility. This midwest US installation is equipped with 17 ounce polyphenylsulfide (PPS) filter bags with single top removal clean air plenum doors for ease of maintenance.

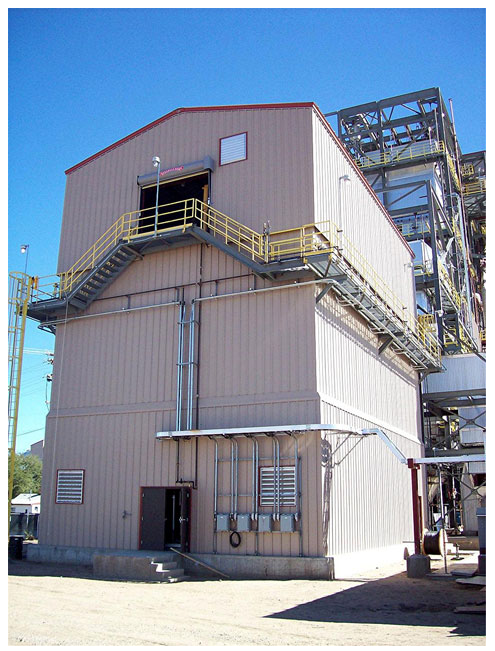

Sixty Five Megawatt Utility Power Boiler Baghouse designed to filter 225,000 ACFM at 325°F. The eight module baghouse incorporates long bag cleaning technology and penthouse plenum top removal door system for ease of maintenance. The flue gas filtered is generated from the circulated fluid bed combustion of various blends of low to medium sulfur coal. The filter media is laminated with a PTFE membrane to provide very low outlet emissions.